Continuous improvement

UTOC APPROACH TOWARDS PRODUCTIVITY PERFORMANCE

Inclusive Growth through Innovation, Mechanization, Automation and Digitalization. We constantly explore new technology, software, hardware and method to improve our Productivity Performance.

Mechanization

To increase productivity and reduce manpower. UTOC is looking at ways to adopt automation to reduce reliance on workers for manual operations. This not only improves productivity but also reduces possible risk of industrial mishaps. Safety is of paramount importance in the process industry as any industrial accident could lead to serious impact on the lives of employees and production downtime.

Innovation

Explore new method to improve the efficacy of our work.

Digitization IT Systems

UTOC has implemented the following systems to improve productivity for data handling and traceability;

SYSTEM

UWIS – UTOC Welding Inspection System.

Type

Software – Internet Web Base, UTOC custom program.

Purpose

Weld records data entry and generating welding log sheets

Advantage

1) Easy accessible at anywhere with internet connectable, and anytime.

2) Data is secured with password and real time accuracy.

3) Fast in generating precise reports.

4) Fail proof approach in generating welding log sheets.

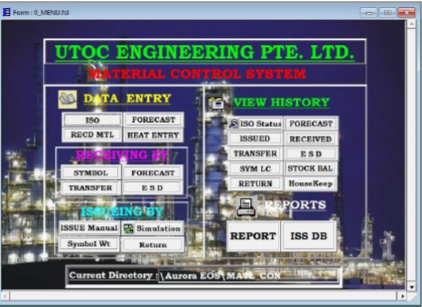

SYSTEM

Piping Fabrication & Installation Tracking System.

Type

Software

– Paradox, customized program.

Purpose

Material control log sheet.

Advantage

1) Enhance data accuracy in recording and retrieving.

2) Able to generate productivity status for piping works.

3) Compatible with bar coding system improving traceability.

SYSTEM

Material Tracking System.

Type

Hardware – Cipher Lab Scanner device

Purpose

Barcode scanner

Advantage

1) Portable handheld with data storage.

2) Accurate data collection and retrieving.

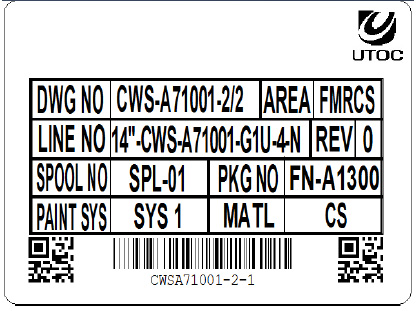

SYSTEM

Material Tracking System.

Type

Hardware

– Bar Tender Labeling Machine.

Purpose

Barcode Labeling Sticker

Advantage

1) Able to generate barcodes and labeling in materials identification.

2) Fast and accurate.

SYSTEM

Store Inventory System

Type

Software – Microsoft Access customized program.

Purpose

Store materials movement recording log sheet.

Advantage

1) Accurate and traceable inventory data.

2) Secured with user passwords.

SYSTEM

Project Scheduling System

Type

Software

– Primavera

– Microsoft Project

Purpose

Project Scheduling

Advantage

1) Enhance project scheduling and resource planning.

2) Accurate in progress tracking and reporting.

3) Widely use internationally.

SYSTEM

Steel Structure Design & Fabrication System.

Type

Software – Tekla X-Steel

Purpose

Design steel structure and generating drawings for fabrication and installation.

Advantage

1) Optimize the fabrication process with intelligent interfaces.

2) Manage changes in a 3D model and save time.

3) Time saving in material take off.

4) Coordinate and communicate in 3D with other departments and project parties.

SYSTEM

Piping Spooling System

Type

Software

– Spoolgen

Purpose

Piping spooling generation program.

Advantage

1) Increases productivity and efficiency in spool drawing generation.

2) Reduces waiting time in fabrication shop.

3) Eliminate waste and surplus materials.

4) Optimized, accurate delivery to construction/ assembly site.

5) Efficient management of spools and erection materials.

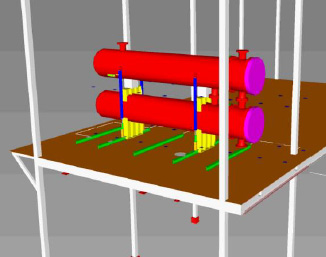

SYSTEM

3D Modeling

Type

Software – AutoCAD, & Navisworks Simulate

Purpose

Feasible studies & pipe spooling identification studies.

Advantage

1) Enhance better understanding in conceptual design transition to workforce easily.

2) Effective planning and execution.